High-Precision Soldering Solution for Complex Connectors | Reduce 30% Labor Costs.

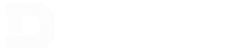

DL-WS-150/200 Series Intelligent Semi-Automatic Soldering Machine

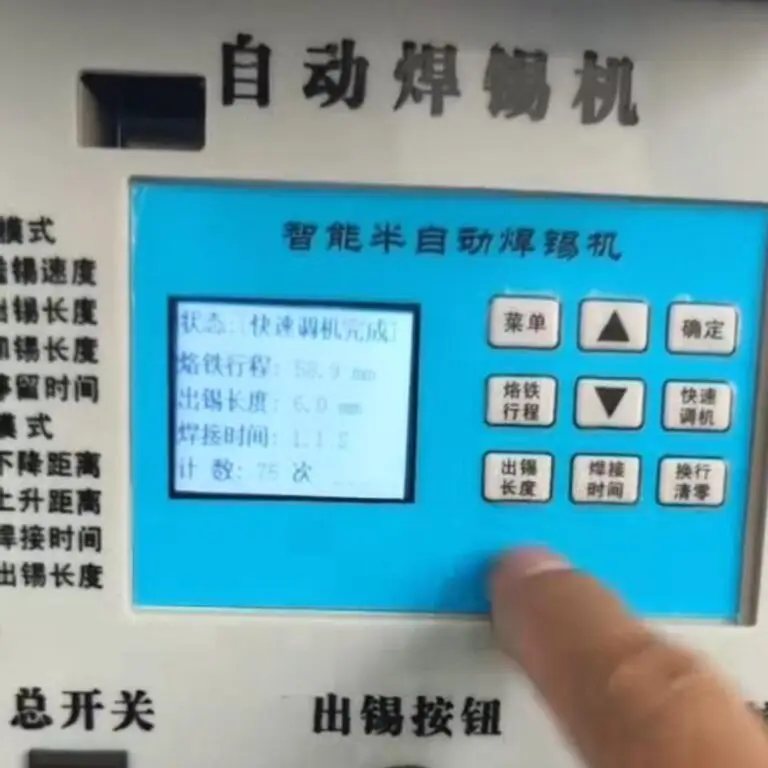

Solve cold joints on complex connectors (XT60, MIL-DTL-38999) with our exclusive “Tri-Core” technology. Designed specifically for High-Mix, Low-Volume (HMLV) production where full automation fails.

Why upgrade?

Stop Cold Joints

PLC intelligent control ensures ±2℃ temperature stability. Eliminate manual errors and guarantee perfect wetting every time.

Double Efficiency

Hands-free pedal operation allows the operator to load the next wire while the robot solders. One operator can effectively manage dual workstations.

Master "High-Mix"

Don't buy a $20k robot for small batch orders. Switch custom fixtures in 3 minutes. Perfect for rapid changeovers between varying wire gauges and connectors.

It Learns. It Mimics. It Holds.

The 3 pillars making DL-WS the ultimate all-rounder.

Auto-Memory & Instant Setup

A robot is useless if the part moves. We don’t just sell machines; we engineer the hold.

Tailored Design: We design CNC-machined Aluminum/POM fixtures specifically for your housing shape.

Plug & Play: Utilizing the standard Fixture Baseplate interface (Manual Sec 5.6), you can swap product lines without tools.

Secondary Feed Technology

Static feeding causes cold joints. Our exclusive algorithm mimics a master technician’s hand motion:

Preheat: Initial contact activates the flux.

Micro-Retract: The wire pulls back slightly to allow thermal recovery and wetting.

Refill: Final solder is pushed in to create a plump, shiny joint.

Custom Engineered Fixtures

Forget complex CNC programming.

Smart Teach: Simply pull the soldering head to the target spot and tap the pedal. The machine automatically learns and calculates the Z-axis travel distance (Manual Sec 2.2).

Recipe Storage: Save up to 10 different product groups (Manual Sec 3.1). Switch from soldering an XT60 to a delicate PCB connector in seconds by calling up “Group 1” or “Group 2”.

One Machine. Limitless Applications.

From micro-switches to heavy-duty battery cables. See the DL-WS-200 adaptable performance in action.

- Universal Head: Compatible with 360° rotary tips for circular connectors.

- Wide Range: Handles 30AWG delicate wires up to 8AWG battery cables.

- Clean Process: No solder splash, no flux residue issues.

Supported Connectors & Custom Fixtures

Whether for Aerospace, Defense, or New Energy, we have the nozzle and fixture ready.

Other Supported Connectors

Whether for Aerospace, Defense, or New Energy, we have the nozzle and fixture ready.

Complete support for Series I, II, III.

Amphenol LJT06R, TV06, TVP00R; Souriau 8LT, 8D Series; Glenair MS27467, D38999.

Amphenol Aerospace manufactures a variety of MIL-DTL-38999 connector solutions like Series III, II, I, SJT, and Aquacon. These Amphenol interconnect solutions support military, aerospace, and defense applications.

Standard MS3470, MS3472, MS3475 (RFI Grounding); Amphenol PT00, 62GB Series

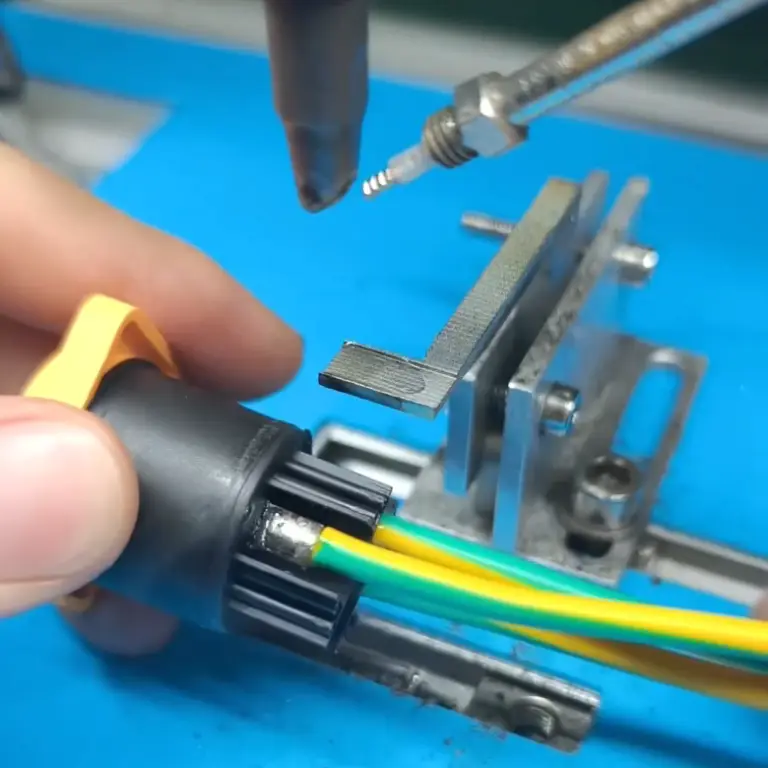

Amass XT30/XT60/XT90, AS150; Anderson Power SB Series; 8AWG – 16AWG Battery Cables.

Need Finished Cable Assemblies Instead?

Don’t want to invest in equipment yet? Our Hiconnector division offers custom cable manufacturing services using these exact Daolai robots. We verify the process by manufacturing for you.

Power Selection Guide (150W vs 200W)

DL-WS-150 (Precision)

Best For: Electronics & PCB

Use Case: PCB THT, USB, Sensors, Small Wires (20-28 AWG).

Benefit: Gentle thermal profile for heat-sensitive components.

DL-WS-200 (Powerhouse) ⭐

Best For: New Energy & Heavy Cables

Use Case: EV Battery, XT90, 8AWG Wire, Large Ground Planes.

Benefit: Rapid Thermal Recovery. Prevents solder freezing (cold joints) on massive copper parts.

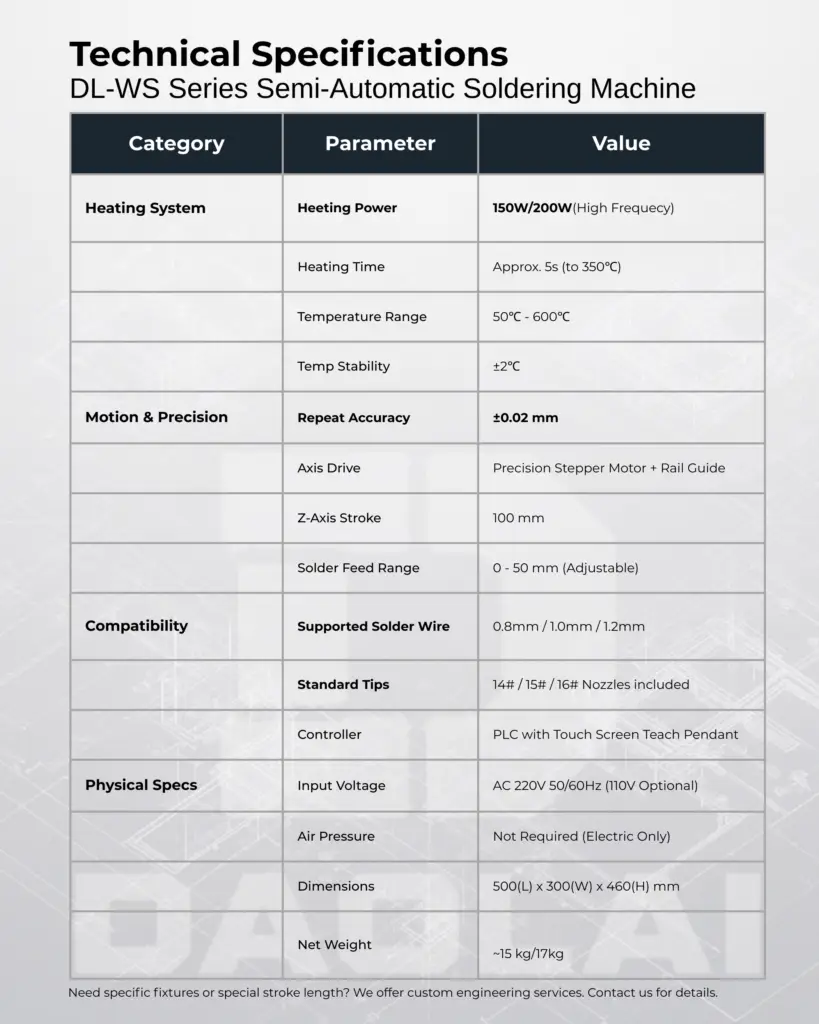

Technical Specifications

Key Specs at a Glance

Power: 150W / 200W High Frequency

Temp Range: 50℃ – 600℃ (±2℃ Stability)

Accuracy: ±0.02mm Repetition

Stroke: Z-Axis 100mm

Input: 110V / 220V (Global Voltage Support)

Due to proprietary design, technical details are available upon request for verified manufacturers only.

Production Bottleneck? Double Your Throughput.

Unlock our Dual-Head & Triple-Head Custom Solutions.

Designed exclusively for high-volume manufacturing (e.g., Motors, LED Arrays, Multi-pin Connectors). Our proprietary multi-spindle technology allows simultaneous soldering, reducing cycle time by 50% – 66%.